Technology Consulting and Engineering Services

Although there are many ways to help our customers, most often applied processes when iXent comes to the playfield are:

- Concept development starting from scratch and realize the final product together with the customer.

- Consult with the customer in specific areas or troubleshooting, realize solutions for the given tasks.

Both processes are founded on our experience and expertise in the field of mechanical and lightweight engineering. Our vast experience in automotive industries and high performance racing environments helps to adapt quickly to customers objective, may it be performance or economics or ideally both.

Feasibility

In the early stage of a project extensive overall understanding of mechanical systems as well as other technical systems is essential. In accessing feasibilities we use the appropriate tools for this phase. Usually starting with sketches and handcalcs to get a good overall understanding of the systems we are looking at.

Concepts

We offer lightweight specific consulting to realize your targets for components or systems. We strongly believe in hybrid lightweight design and are not focused on a specific material although we love composites.

"Right material in the right place"

– this is not only a sentence at iXent, it is our guideline.

Functional integration is a key to generate economical solutions, especially within composites. When developing concepts, we are always looking for opportunities to integrate more than one target, this is how innovation starts at iXent.

Even in this early stage, competitive analysis/simulation with the appropriate tools plays a decisive role.

Leading Projects

With the experience of various senior positions in more than 25 years of professional career both in large cooperation (BMW Group) and in professional racing teams we led numerous projects.

General R&D

Methodical, scientific work in research and development, coupled with a pragmatic approach to complex topics is the core value of iXent’s philosophy.

Structural Simulation and Numerical Optimization

Simulation enables us to assess costs, lightweight objectives and functional performance. We use the latest simulation methods and advanced analysis models added with our own software tools. But this does not hold us back to check result feasibility in every stage of a project by using handcalcs – unfortunately a dying species in “modern companies”.

We perform the following analysis types:

- Statics (linear/nonlinear) / Dynamics / NVH

- Crash

- Numerical Optimization

- Topology Optimization

- Property optimization

- Shape Optimization

- Laminate Optimization (Composites)

Aerodynamics / Hydrodynamics

Our latest and at the same time our oldest passion – When working in the America’s cup we had substantially influence on the innovative foiling systems in AC34 and AC35. Working with Hal Younggreen and Len Imas sparked the idea of reactivating our knowledge on Aero- and Hydrodynamics . Thomas worked during his university years with Richard Eppler, so airfoil development was the natural start for ixent and we expand logically into CFD.

Current development for an Olympic kitefoil system is the result of this process. Black east RX series stands for bike wheel developed by iXent.

Our Aerotools are:

- CFD

- VLM

- Airfoil Development

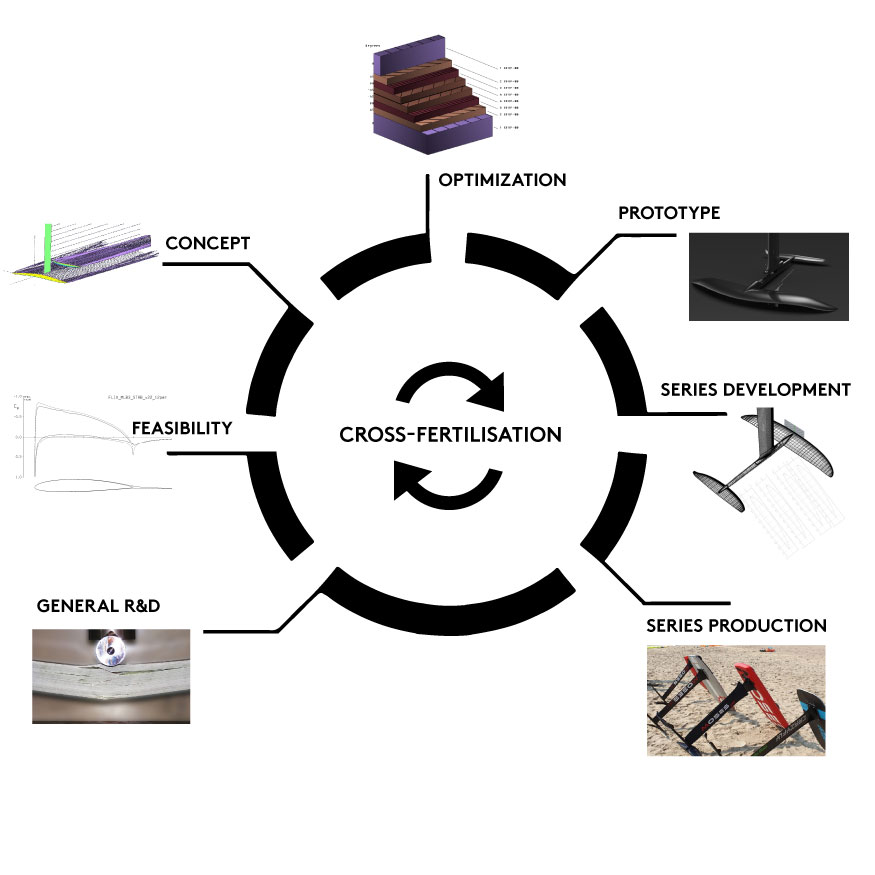

Cross-fertilisation

It is our strong believe that cross-fertilisation of the different phases of a development process is essential for the success.

Experience in series production is the key to designing a robust concept avoiding unpleasant surprises during the project..

As well as profound engineering and series knowledge generates concepts with the right genes to make it into series production.

Network – Prototype / Series Development and Production

We are proud of our network partners. After more than 10 years of collaborative work we offer our customers a full service support from first sketches to the finished hardware. Various projects show the success of this alliances from prototype hypercars to serial production sporting goods. Our network partners emphasis spans from scientific engineering to precision lightweight manufacturing.